PET release film is a material commonly used in thermal transfer. The base film is PET film. It is coated with silicone, so it is also called Silicone coated PET release film or Silicone PET Release Film.

PET release film Classifications

1–By Sides

It can be divided into single-sided release film and double-sided release film.

2—By release force

It can be divided into light release film, medium release film, and heavy release film.

5G,10G,15G,20G,25G,30G,35G,40G,45G,50G,60G,70G,80G,90,100G,120G,150G,160G,200G,250G,300G,400G,500G,600G,700G,800G,900G,1000G,1100G,2000G。

3–By thicknesses

0 .012mm, 0.019mm, 0.025mm, 0.038mm, 0.05mm, 0.075mm, 0.1mm, 0.125mm, 0.188mm

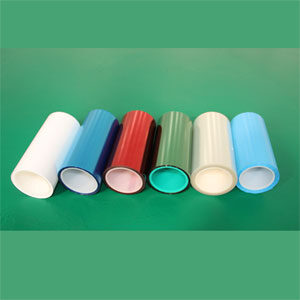

4—By Color

Red release film, yellow release film, green release film, blue release film, milky white release film, yellow release film, matte release film, pearl release film, black release film, transparent release film Film, translucent release film, porcelain white release film.

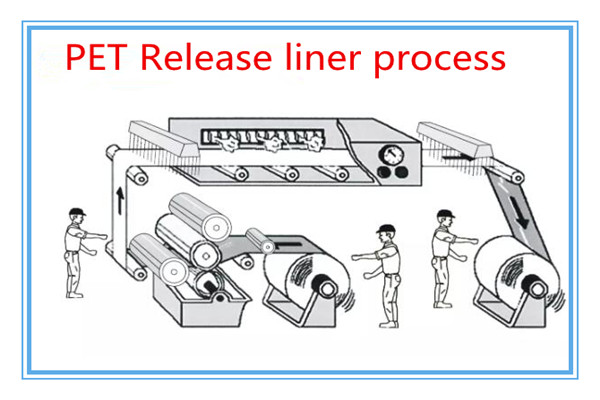

Manufacturing Process of release film

Because the surface of the coating film is smooth and uniform, many disadvantages such as wrinkles, twitches, particles, bubbles. The pinholes have been successfully avoided. Also, it also has excellent physical properties, small thickness tolerances, high transparency, low thermal shrinkage, and good plasticity.

PET release film is mainly used as a carrier for vacuum aluminization. that is, after the PET film is placed in a vacuum aluminizing machine for aluminum plating. The glues is applied to compound with the paper. Then the PET film is peeled off. The aluminum molecular layer is transferred to the surface of the cardboard through adhesion. The so-called aluminized cardboard is formed. The production process of aluminized cardboard is PET base film → release layer → color layer → aluminized layer → glue layer → transfer to cardboard.

Our pet release film,silicone-coated pet film is produced in a cleanroom environment, key parts like coating head at 1000 class cleanroom. It process like below:

The PET release film manufacturer is equipped with a large slitting and slicing machine, which can be slit and sliced according to your specifications.

What is PET release film used for?

PET release film is now widely used in packaging, printing, screen printing, pad printing, nameplates, membrane switches, flexible circuits, insulation products, circuit boards, laser anti-counterfeiting, laminating, electronics, sealing materials, reflective materials, waterproofing, etc. field. Materials, medicine (gypsum paper), toilet paper, adhesive products, die-cutting, and stamping processing industries.

Related Products