What is Thermoforming?

Thermoforming is a plastic processing technology. The main principle is to heat the flat hard plastic sheet to soften it. Then it is adsorbed on the surface of the mold by vacuum, and formed after cooling.

Thermoforming,we can see the meaning from the word,Forming via heating process. Thermoforming describes the process of heating a thermoplastic sheet to its softening point, stretching it over or into a single-sided mold, and holding it in place while it cools and solidifies into the desired shape.

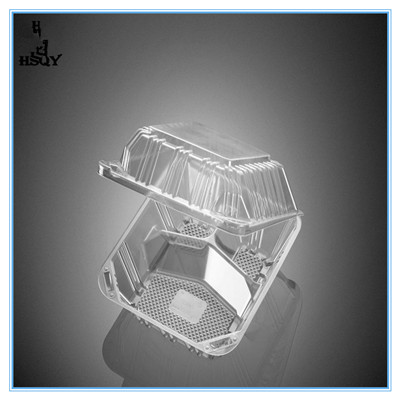

Now many food containers, blister packs, automobile components, home electric appliances, and industrial trays in our daily life are made by a thermoforming process.

The thermoplastic sheet is clamped into a holding device and heated by an oven using either convection or radiant heat until it is softened. The sheet is then held horizontally over a mold and pressed into or stretched over the mold using vacuum pressure, air pressure, or mechanical force. The softened sheet conforms to the shape of the mold and is held in place until it cools. The excess material is then trimmed away and the formed part is released. Excess material can be reground, mixed with unused plastic, and reformed into thermoplastic sheets.

Thermoforming is commonly used for food packaging but has many applications from plastic toys to aircraft windscreens to cafeteria trays. Thin-gauge (less than 0.060 inches) sheets are mostly used for rigid or disposable packaging. While thick-gauge (greater than 0.120 inches) sheets are typically used for cosmetic permanent surfaces on automobiles, shower enclosures, and electronic equipment.

Thermoforming materials

Dehui Film can provide 3 main Thermoforming materials: APET and PETG, PET GAG.

APET

While Apet film is one of the most popular materials for thermoforming. As Apet film is Environment-friendly material. and good performance in thermoforming.

- Normally the thermoforming process like below.

- Heat APET film or other plastic film

- Vacuum the air in the mold in order to evacuate the air

- The plastic sheet is formed according to the mold’s shape

By blowing compressed air into the mold the plastic sheets transform shapely. We have 100% Virgin Resin Apet film for the thermoforming.

PET Film (Polyethylene Terephthalate)/Apet sheet.

PETG

GPET, also known as PETG, is an amorphous PET resin modified with cyclohexanedimethanol. Its melting point is relatively low, only 180℃~200℃. When PETG sheet has the characteristics of the APET sheet, its biggest feature is outstanding heat-sealing performance. It is easy to operate during sealing and the quality of heat sealing is reliable.

Compared with APET, PETG does not crystallize at very high molding temperatures. For vacuum forming, even clear contours of complex geometric shapes can be obtained. However, due to its relatively high price, the application is subject to certain restrictions.

The chemical stability of PETG is the same as that of APET.

Excellent punching and cutting performance, the punching force required is about 10% less than that of APET.

Heat sealing of PETG to coated paperboard, the sealing temperature range is 180~250℃. The sealing time is 1.2~3s. The heat sealing of the coated cover film is 170-200°C. The time is 0.7~2s. PETG or PETG / APET / PETG full plastic cover can be heat sealed. Bonding is the same as APET.

Special composite sheet, PETG / APET / PETG, PETG / PS / PETG, PS / PETG, PETG / PP.

PET GAG

Composite polyester sheet. The bottom and surface layers are PETG, and the middle layer is APET. GAG exists to reduce costs. Both PETGAG and PETG are made by three-layer co-extrusion. Among them, PETG has no crystallization temperature, easy molding adhesion, and non-whitening characteristics. It overcomes the shortcomings of PET that is easy to crystallize and whiten.

The characteristic of PETGAG is that it is easier to heat seal. Compared with other surfaces without a layer of coating, it has no crystallization temperature. So it will not have the problem of fogging.

PETGAG has PETG characteristics on the surface. And PET characteristics on the upper and lower layers, it can replace PETG for cost considerations. Compared with PETG, GAG has an advantage in cost.

The above we explained What is Thermoforming and the thermoforming materials. Dehui is a thermoforming materials supplier and exporter. The 3 thermoforming materials of APET,PETG,PETGAG is our mainly exporting sheet products.

If you have any questions or enquiries,kindly contact us.