What is Mylar or Mylar Film?

Mylar or Mylar Film, also known as BoPET (Biaxially-oriented polyethylene terephthalate) is a polyester film made from stretched polyethylene terephthalate (PET). Mylar film itself is polyester film. So the true generic terms for this material are either polyester film or plastic sheet.

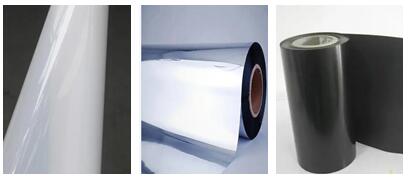

Mylar Polyester film/plastic sheet is manufactured in a range of different styles, finishes, and thicknesses, and many applications.

Dehui Film offers a wide variety of different types, grades, finishes, and thicknesses of polyester film / plastic sheet.

Mylar Features:

- Dimensionally stable

- Straight and excellent tear strength,

- Heat-resistant and cold-resistant,

- Moisture and water resistance,

- Chemical resistant,

- Super insulation performance,

- Excellent electrical, mechanical, heat, and chemical resistance properties.

What are the Types of Mylar Films and Sheets

- By Property

- Anti-static

- Adhesion treated

- Metallized ()

- Barrier coated

2. By Finishes of Mylar Sheets

- Clear

- White

- Low, Moderate to High Haze

- Black

3.By The thickness of Mylar Sheets

- 0.025mm

- 0.050mm

- 0.075mm

- 0.10mm

- 0.125mm

- 0.188mm

- 0.25mm

- 0.35mm

4. By Mylar Application type

Insulating type, cushioning type, wear-resistant type, sealed type, and appearance decoration type.

Are all types of Mylar film / Mylar sheets available in all finishes and thickness?

No. Different types and finishes of polyester film and sheet are made for specific applications. Learn more about different types and finishes of polyester film and sheet and the properties of Polyester Film and Sheet.

What is Mylar Made of

To make Mylar, super-heated polyethylene terephthalate (PET) film is put on a roll and stretched. One side is smooth, but the other is not so that it can be applied more easily as a coating to various products, such as paper.

Molten polyethylene terephthalate (PET) is extruded as a thin film onto a chilled surface, such as a roller.

The film is drawn biaxially. Special machinery may be used to draw the film in both directions at once. More commonly, the film is drawn first in one direction and then in the transverse (orthogonal) direction. Heated rollers are effective for achieving this.

Finally, the film is heat set by holding it under tension above 200 °C (392 °F).

A pure film is so smooth it sticks to itself when rolled, so inorganic particles may be embedded in the surface. Vapor deposition may be used to evaporate gold, aluminum or another metal onto the plastic.

Why Choose Mylar Film?

Mylar polyester film is one of the world’s most recognized and widely used polyester films.

It has been a prominent film in a variety of applications across electronics, food packaging, industrial specialty, cast & release, and graphics markets due to its balanced tensile properties, good adhesion, excellent moisture, and chemical resistance.

Mylar polyester films are ideal products for high volume, dependable industrial performance, where lower-cost initiatives must be met.

Why Choose Dehui?

It’s our mission to delivering you the right mylar film and sheet, on time, every time. Quality stable, delivery promptly, Price competitive. we’re also committed to environmental sustainability.

If you have inquiry about mylar films, email us: info@dhfilmtech.com