PET film is polyethylene terephthalate. It has excellent physical properties, heat resistance, chemical resistance and dimensional stability.

With the development of technology, PET film has also been widely used. Such as glass fiber reinforced plastic industry, building materials industry, printing industry, medicine and health. In our life, a lot of packaging for food, medicine, etc. is made of PET film.

As a type of PET product, PET film can be recycled again and again. Recycled PET film can be used in containers for food, beverage and personal care products. Can also be used in carpets, clothing, auto parts, building materials, industrial strapping and many other products.

The Difference Between PET and PET Film

PET is polyester resin, which is a milky white or light yellow crystalline polymer. The full name of pet is Polyethylene terephthalate, which is the most important variety in thermoplastic polyester.

PET has the advantages of smooth surface, rich luster, abrasion resistance, dimensional stability, low wear, high hardness, good electrical insulation, low temperature, non-toxic, low water absorption, weak acid and organic solvent resistance. ,

PET is mainly used for fibers, and a small amount is used for films and engineering plastics. Among them, PET fiber is mainly used in the textile industry, and PET film is mainly used in electrical insulating materials.

PET film is made from PTA.

PET Film Production Process

A typical PET film processing process is the following steps:

1. The blank slices, mother slices and recycled materials are re-granulated and fed to each silo through the fan.

2. Then automatically batch and mix the materials according to the given ratio, and then enter the pre-crystallizer for pre-crystallization after mixing evenly.

3. After the raw material is pre-crystallized, it enters the drying tower for drying.

4. The dried raw material enters the extruder. The raw material is heated and melted in the extruder, passes through the metering pump, filter and adapter, and then reaches the die to form a thick sheet.

5. After the polyester melt flows out from the die lip of the die head, it is pressed onto the quenching roll by the adsorption system to rapidly cool the cast sheet.

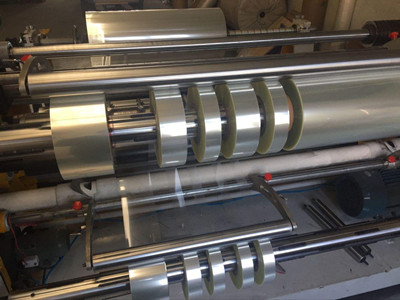

6. The thick sheet is stretched by the longitudinal stretching machine and then enters the transverse stretching system for transverse stretching, and finally passes through the traction system to the winding system to wind up large film rolls.

7. Finally, according to the customer’s specifications, it will be cut, inspected and packaged for storage.

PET Film Properties

1. It has good mechanical properties, the impact strength is 3 to 5 times that of other films, and the folding resistance is good.

2. Oil resistance, fat resistance, dilute acid, dilute alkali, and most solvents.

3. It has excellent high temperature resistance and low temperature resistance performance. PET film can be used in the temperature range of -70°C to 150°C with little effect on its mechanical properties.

4. It has excellent gas barrier, water, oil and odor properties.

5. High transparency, can block ultraviolet rays, and have good gloss.

6, Non-toxic, tasteless, good hygiene and safety, can be directly used for food packaging.

PET Film Application

PET film was first discovered in the late 1950s. The researchers found a way to make PET film by stretching a thin sheet of extruded PET film. The earliest applications of PET film at the time were video, photographic and x-ray films and packaging films.

PET is an inert material, non-toxic, odorless and non-reactive with food. Therefore, PET films are also widely used in the packaging of food, beverages and pharmaceuticals. It has also been proven that PET film is very safe to use with food and beverages.

Of course, in addition to the above two applications, PET film is also widely used in the following fields:

- High-grade packaging materials for textiles, precision instruments and electrical components;

- The base material of audio tape, video tape, film film, computer floppy disk, metal coating and photosensitive film;

- Electrical insulation materials, capacitor films, flexible printed circuit boards and membrane switches and other electronic fields and mechanical fields.

PET films are available in hundreds of different thicknesses and coating combinations. And PET film has shown excellent performance in many fields.

Since the establishment of the company, Dehui Film has been engaged in the manufacture and export of packaging series design, development and production of PET film: polyester film, metallized PET film, chemically treated polyester film, milky PET film, PETG sheet, PETG roll lumber, APET sheet, GAG film, GAG sheet, Biodegradable film | PLA film | Multilayer high barrier film.

If you have any questions related to PET film, feel free to contact us.